Table of Contents Show

The construction technology has advanced so much that Portland cement which used to be the only choice for making concrete has lost its coveted seat to geopolymer concrete.

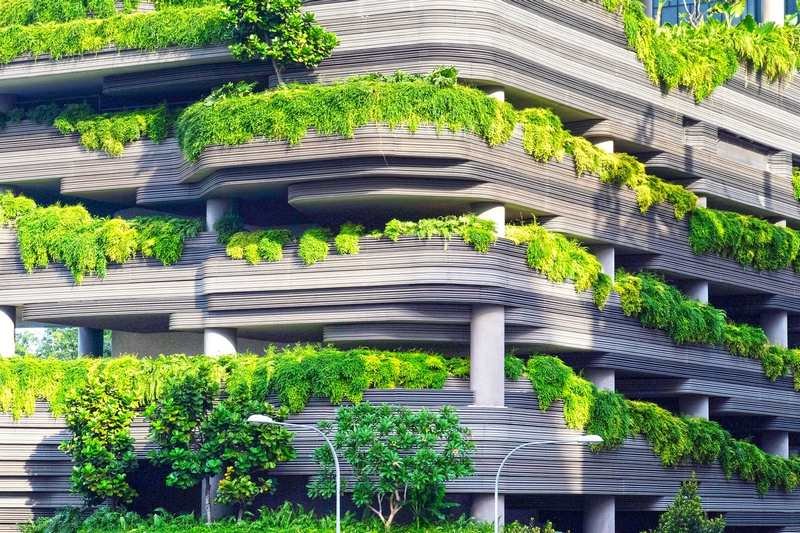

As we are moving more towards eco-friendly construction materials, the innovation of geopolymer concrete is a massive step towards pollution reduction.

The engineers at Blanco Sheds Townsville confirm that Portland cement is harmful to the environment because it emits carbon dioxide that pollutes the environment and geopolymer concrete is highly safe in this regard.

Read Also:

Geopolymer or Green Concrete

Green concrete can be the most suitable moniker for geopolymers that builders can use with confidence without any concerns of adverse effects on the environment.

Invented in 1978, geopolymer cement consists of an inorganic molecule, or networks or chains. You can learn more about the different types of polymer and their properties at polychemistry.com

Geopolymer cement concrete is made from waste materials like granulated blast furnace slag (GGBS) of steel plants and fly ash, a waste product generated from thermal power plants.

Geopolymer cement is the product obtained by processing the mixture of fly ash and GGBS with the help of suitable technology and can become a substitute for Portland cement concrete.

Composition of Geopolymer Cement

Fly ash and GGBS contain several thermally activated natural materials like kaolinite, which is the source of silicon and aluminium. An activated alkaline solution is used for polymerizing the materials into molecular chains and networks that ultimately form a hardened binder.

Geopolymer cement has other names like inorganic polymer cement and alkali-activated cement. To convert the cement into concrete, you must add coarse and fine aggregates to it.

Properties of Geopolymer Cement Concrete

The physical properties of geopolymer cement are as under:

Compressive strength can be as high as 70 N/mm2 and the cement acquires rapidly and much faster than Portland cement. After 28 days, the compressive strength reduces slightly between 60N/mm2 and 70N/mm2. The concrete strength is higher than 25N/mm2 after 24 hours.

Besides the above physical properties, some other properties need special mention.

- Geopolymer concrete is most suited for heavily restrained and thick concrete members because its drying shrinkage is much less as compared to Portland cement concrete and its heat hydration is low too.

- The fire-resisting property of geopolymer concrete is much better than traditional, OPC-based concrete.

- Geopolymer concrete has a low permeability rate, which can be even very low as per the ASTM standard.

- Acid resisting property is also very high for geopolymer concrete as during tests conducted with 2% and 10% sulphuric acid.

Where to Use Geopolymer Concrete?

Although the applications of geopolymer concrete are the same as those of Portland cement concrete, there are some specific areas where the new concrete is most suitable. Geopolymer concrete finds the best application in the construction of water tanks, retaining walls, pavements, and precast bridge decks.

The Global Change Institute, a four-story building of the University of Queensland, has been constructed with geopolymer concrete. The day is not far when this new type of concrete will become the staple choice for builders for all types of construction.

Frequently Asked Questions (FAQs)

Here are five frequently asked questions (FAQs) about geopolymer concrete:

Geopolymer concrete is an eco-friendly substitute for traditional cement concrete. It is crafted by blending industrial by-products like fly ash and ground granulated blast furnace slag (GGBS). These materials are activated with an alkaline solution, resulting in a durable binder.

To produce geopolymer concrete, you’ll need: – Fly ash: A byproduct obtained from thermal power plants. – GGBS: A byproduct derived from steel plants. – Coarse and fine aggregates (similar to those used in conventional concrete). – An alkaline activator solution that plays a pivotal role in activating the source materials rich in silicon and aluminium, such as fly ash and GGBS.

Compressive strength: Geopolymer concrete demonstrates impressive compressive strength, reaching up to 70 MPa (N/mm²). It attains this strength rapidly, surpassing the early strength development of ordinary Portland cement concrete. After 24 hours, its compressive strength exceeds 25 MPa, while after 28 days, it ranges between 60 and 70 MPa.

Geopolymer concrete champions sustainable construction practices by reducing waste and diminishing carbon emissions. It mitigates the demand for Portland cement, making it an environmentally friendly choice.

While geopolymer concrete offers numerous benefits, it’s essential to consider factors such as the availability of raw materials, initial cost, and specialized knowledge required for its production and application.

Remember, geopolymer concrete is a promising solution for eco-conscious construction practices!