Table of Contents Show

Thin-pour epoxy coasters are a popular choice for DIY enthusiasts and crafters who want to create personalized and functional pieces. Epoxy resin provides a glossy, durable finish that enhances the beauty of your coasters while protecting them from moisture and wear.

In this step-by-step guide, we will walk you through the process of applying thin-pour epoxy to create stunning coasters that will impress your guests.

1. Gather Your Materials

Before you begin, ensure you have all the necessary materials:

- Wooden or silicone coaster molds

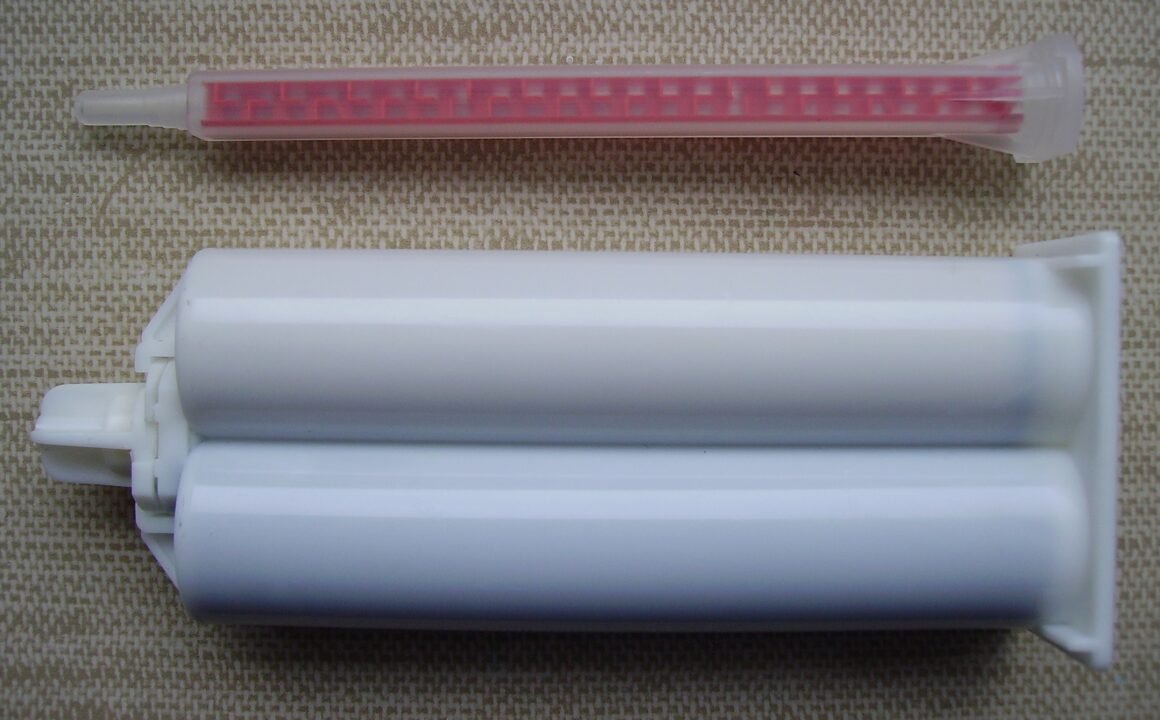

- Epoxy resin (specifically formulated for thin pours)

- Mixing cups and stir sticks

- Heat gun or torch

- Protective gloves and safety goggles

- Optional: Alcohol ink, pigments, or glitter for customization

- Sandpaper (various grits) and polishing compound (for finishing)

2. Prepare Your Workspace

Creating a clean and organized workspace is crucial for a successful Epoxy Coasters. Follow these steps:

- Choose a well-ventilated area with minimal dust and debris.

- Cover your work surface with a plastic sheet or craft paper to protect it from resin spills.

- Clean and dry your coaster molds thoroughly to ensure a smooth finish.

3. Mix and Pour the Epoxy Resin

Now, let’s dive into the process of mixing and pouring the epoxy resin onto your coasters:

- Read the manufacturer’s instructions for the epoxy resin and follow the recommended mixing ratio.

- Wear protective gloves and safety goggles to avoid skin contact and eye irritation.

- Pour the appropriate amounts of resin and hardener into a mixing cup.

- Stir the mixture gently but thoroughly for the recommended time to ensure proper blending.

- Optional: Add alcohol ink, pigments, or glitter to the mixture if you want to customize the coasters.

- Let the mixture sit for a few minutes to allow any air bubbles to rise to the surface.

4. Apply the Thin Pour Epoxy

With your resin mixture ready, it’s time to apply it to the coaster molds:

- Slowly pour the resin mixture into each coaster mold, starting from the center and working your way out.

- Use a stir stick or toothpick to guide the resin to the edges of the mold, ensuring even coverage.

- Gently tap the molds on the table to help release any trapped air bubbles.

- Use a heat gun or torch to lightly pass over the surface of the resin to eliminate bubbles and create a smooth finish.

- Let the coasters cure in a dust-free area for the recommended time, typically 24 to 48 hours.

5. Finishing Touches

Once the epoxy resin is fully cured, you can add the finishing touches to your coasters:

- Carefully remove the coasters from the molds. If using silicone molds, flex them to release the coasters easily.

- Use sandpaper of varying grits to sand down any rough edges or imperfections on the coasters.

- Wipe the coasters with a damp cloth to remove any sanding residue.

- Apply a polishing compound to a soft cloth and gently buff the surface of the coasters to restore their shine.

- Allow the coasters to dry completely before using or gifting them.

Frequently Asked Questions (FAQs)

How long does it take for thin-pour epoxy coasters to cure?

Thin-pour epoxy coasters typically take 24 to 48 hours to cure. However, it’s essential to check the manufacturer’s instructions for the specific curing time and environmental conditions required.

Can I use any type of mold for thin-pour epoxy coasters?

You can use wooden or silicone molds for thin-pour epoxy coasters. Silicone molds are popular because they provide flexibility, making it easier to remove the coasters once cured. Wooden molds can add a rustic touch to your coasters.

How do I prevent air bubbles from forming in my thin pour epoxy coasters?

To minimize air bubbles, make sure you mix the epoxy resin thoroughly but gently. Pour the resin slowly into the molds and use a heat gun or torch to remove any surface bubbles that appear during the pouring process.

Can I add designs or images to my thin-pour epoxy coasters?

Yes, you can add designs or images to your coasters by using techniques such as decoupage or by embedding items like dried flowers or small trinkets. Ensure that any materials you use are compatible with epoxy resin and won’t bleed or fade over time.

How do I clean and maintain thin pour epoxy coasters?

To clean your epoxy coasters, simply wipe them with a damp cloth or mild soap and water. Avoid using abrasive cleaners or scrubbing pads that could scratch the surface. With proper care, your coasters will maintain their beauty and functionality for a long time.

Conclusion

Creating thin-pour epoxy coasters is a rewarding and enjoyable crafting experience. By following this step-by-step guide, you can confidently apply epoxy resin to your coasters, resulting in stunning and functional pieces.

Remember to gather all necessary materials, prepare your workspace, mix and pour the epoxy resin carefully, and apply the finishing touches after the curing process.

With a little creativity and attention to detail, you’ll have beautiful coasters that will impress your guests and add a personal touch to your home decor. Enjoy the process and happy crafting!