Table of Contents Show

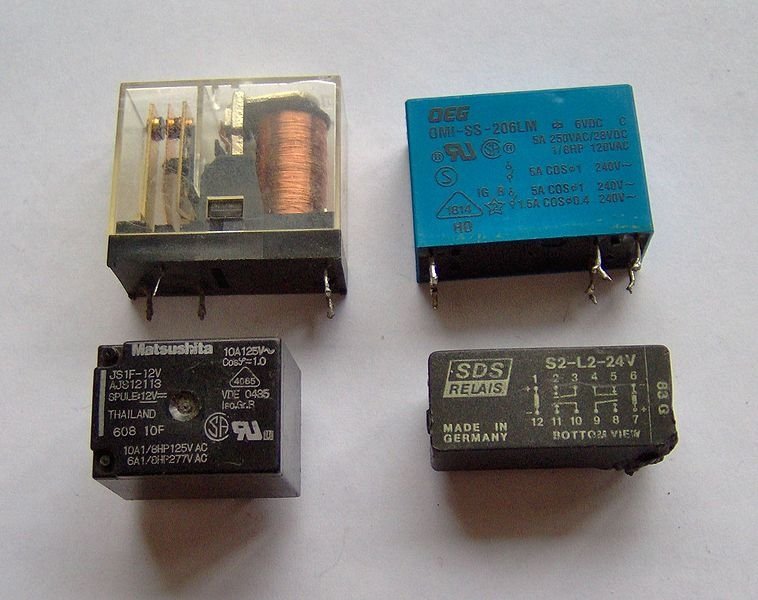

Even though electromagnetic relays are no longer used in some situations because of newer technologies, electromechanical relays still have a lot to offer.

These strong and versatile relays are good for high voltage applications or those that need galvanic isolation between terminals.

They come in almost every type you can think of, for signal and power uses. Because of their large, strong contacts, they can handle voltage surges, but this also makes them take 5 to 15ms longer to switch and make them bigger overall.

There are also types that latch, which save energy because they only need a short pulse to switch. They don’t need the energy to stay switched, just to switch.

Reed relays, which have thinner contacts, can switch about ten times faster, but they can be damaged by arcing, which happens when the contacts get too hot. They last longer mechanically than other types of electromechanical relays, but they aren’t usually used for low voltage applications because, at high temperatures, they can produce a thermal EMF that could mess up a low voltage signal.

Semiconductor Relays Switch Faster at Low Voltages

They don’t have any moving parts, which makes them more reliable and gets rid of the noise. Most of the time, they use optical isolation. The control circuit turns an LED on or off, and the photosensitive MOSFET switches in response.

This is much faster (1ms or less, depending on how long it takes the LED to turn on and off), but there is no isolation between the contacts. There is isolation between the control side and the switching side, but not between the contacts.

When compared to electromechanical types, the contact resistance is much higher because it is based on the on-resistance of the MOSFET. These parts are often used in applications that need to be reliable and last a long time.

FET switches are another type of semiconductor relay. They use a series of CMOS transistors without any isolation. These are the fastest relays to switch, and they are also the smallest. They have a long life, but, like SSRs, they have a relatively high on-resistance.

MEMS Relays Have Some Qualities of Both Types

MEMS has been suggested as a way to combine the best parts of both electromechanical relays and semiconductor relays. It’s basically a very small electromechanical switch on the same scale as CMOS devices, but instead of electromagnetism, it uses electrostatic forces to bend the tiny contacts together.

They can be made small, dense, and linear, which makes them perfect for switching RF signals. They also save a lot of energy because it doesn’t take much power to turn them on or keep them on. But the main problems are still isolation, reliability, and cost, with moisture getting in and mechanical weakness close behind.

Reliability Ratings are Often Made Up

Reliability ratings for relays are prone to speculating, just like most ratings for electronic parts. It’s important to pay close attention to how the manufacturer shows reliability numbers and to make sure you’re comparing apples to apples.

Manufacturers check the quality of their Chint relays by taking a sample from each batch they make and testing it until it breaks. This testing should be done at the rated load and at the highest temperature at which the device can work.

Usually, they test until they reach the minimum rated life of the relay. Any failures in the sample size are then used to figure out how reliable the whole thing is.

Make sure the sample size is big enough and that the tests are run under the right conditions. Relays should be tested at their highest operating temperature and at full load, but this may not be the same for all manufacturers. What is the definition of a failure? Check how one cycle or one operation is defined for relays with more than one pole or more than one throw.

Reliability Numbers Don’t Show What’s Really Going On

Obviously, the numbers on the data sheets don’t really show how reliable the product will be in real life. First of all, the number given does not work for all load conditions. The operating conditions are also likely to be very different from what the manufacturer tested in.

For example, systems in real life may be exposed to heat, dust, dirt, humidity, and/or corrosive gasses, which can cause problems. Electrical factors that shorten the life of SSRs include the ratio of on-time to off-time, exposure to voltage spikes from the line, and switching on and off while the SSR is still hot.