Table of Contents Show

Welcome to the comprehensive guide on cutting tempered glass – a material renowned for its strength and safety. Navigate your way through the key considerations, understand the annealing process, and explore the step-by-step guide to cutting tempered glass safely. Discover why professional assistance is recommended, learn about the essential materials for sanding, and unravel the importance of positioning the sandpaper at a perfect 45-degree angle. Let’s embark on this journey to wield tempered glass with precision and safety!

Understanding Tempered Glass

Tempered glass, often referred to as toughened glass, is widely acclaimed for its strength and safety. The manufacturing process involves thermal and chemical treatment that enhances its durability. This fortified nature of tempered glass sets it apart from normal or untempered glass, making it a preferred choice for various applications.

This type of glass is commonly used in various scenarios due to its safety features, some of which include:

- Vehicle windows: To protect passengers in case of accidents

- Tabletops: For their resistance to heat and pressure

- Shower doors: Due to their shatterproof nature

- Fireplace doors: Thanks to their heat resistance

For more information on the application of this safety glass, visit this link.

Cutting Tempered Glass

The process of cutting tempered glass differs significantly from that of cutting ordinary or untempered glass. It requires careful execution and specialized techniques to prevent unnecessary damage or breakage. Here’s a step-by-step guide on how to handle this task:

- Understand the Properties of Tempered Glass: Before proceeding with any cuts, familiarize yourself with the physical properties and characteristics of the tempered glass. This will help you understand how best to handle it.

- Prepare Your Work Area: Ensure your workspace is clean, safe, and adequately lit. Remember, safety should always be your priority.

- Measure Accurately: Use a tape measure to get the exact dimensions needed for your project.

- Mark Your Cut Lines: With a marker pen, trace out your cut lines on the surface of the tempered glass.

- Use an Appropriate Cutting Tool: Utilize a diamond-tipped glass cutter for best results.

Remember, cutting tempered glass may require professional assistance due to its unique properties.

Note: For the best deals on Storefront doors in Toronto Building Material Doors, explore the largest online selection.

Key Considerations Before Cutting Tempered Glass

When it comes to cutting tempered glass, a unique process must be followed for successful results. The technique is widely recognized as the annealing process. This procedure effectively reverses the tempering process that originally gave the glass its strength.

The Annealing Process

The annealing process involves a carefully controlled heating and cooling cycle. Here’s how it works:

- Heating: Start by heating the tempered glass pane to approximately 1,000 °F (538 °C). This temperature is crucial as it allows the internal structure of the glass to relax, thereby undoing the tempering.

- Cooling: After heating, you need to gradually cool down the glass. Rapid cooling would stress the material and could lead to breakage.

By controlling this heat treatment process, you can bring the tempered glass back to a state where it can be cut without shattering.

Safety Precautions and Professional Assistance

Bear in mind that this annealing process weakens the glass enough so that it can be cut properly without any breakage. However, this procedure requires extreme care and precise control of temperature changes.

Note: It’s important to remember that this procedure should only be attempted if you have access to a kiln or other appropriate equipment. If not, it’s recommended that you seek professional assistance for cutting tempered glass safely without damaging it.

This guidance is not only for preserving your material but also for ensuring your safety during the process.

Remember: working with high temperatures and delicate materials always carries some level of risk. Therefore, if you’re unsure about any step in this process, don’t hesitate to contact a professional who can handle this task efficiently and safely.

Steps to Cut Tempered Glass Safely

Cutting tempered glass requires meticulous attention to detail and careful handling, as the annealing process reduces the glass’s strength. To prevent shattering, it’s crucial to follow a systematic step-by-step procedure.

Below is a simple seven-step guide that will help you cut tempered glass safely and accurately:

✔ Step#1: Cleaning Surface

The first step to cutting tempered glass safely is ensuring that the annealed glass surface is thoroughly clean. This is crucial as any dirt or debris can interfere with the cutting process and lead to less-than-desirable results.

Here are detailed steps on how to properly clean your annealed glass:

- Choose Your Cleaner: There are numerous glass cleaners available in the market. It’s recommended to use a product specifically designed for glass cleaning, which will effectively remove dirt, smudges, and fingerprints without leaving streaks or residue.

- Apply Cleaner: Spray your chosen cleaner evenly across the glass surface. Ensure you’re covering all areas, especially those with visible marks or dirt. Allow the cleaner to sit for a minute to break down any stubborn stains.

- Wipe Down Glass: Use a lint-free clean cotton cloth to wipe down the glass pane. The cloth should be clean and dry to prevent leaving any lint or moisture behind, which could affect the cutting precision later on.

Remember: The aim is not just making the glass visually clean but also ensuring it’s perfectly dry and free from any residues or particles that may interfere with the cutting process.

- Repeat if Necessary: If after wiping, you still notice marks or residues on the glass, repeat the process until you achieve a perfectly clean surface.

By following these steps, not only will you ensure a successful cutting process but also extend the lifespan of your tempered glass by maintaining its pristine condition.

✔ Step#2: Ensure Safety

Before you begin the process of cutting tempered glass, it’s imperative to prioritize your safety. The annealing process transforms the tempered glass into a more fragile state that can shatter into sharp pieces if mishandled. Protecting yourself adequately is therefore vital to prevent any unforeseen accidents.

- Safety Goggles: Your eyes are one of the most sensitive parts of your body and need the highest level of protection. Always put on safety goggles before you start working with glass. These goggles will guard your eyes against any potential shards that could fly off during the cutting process.

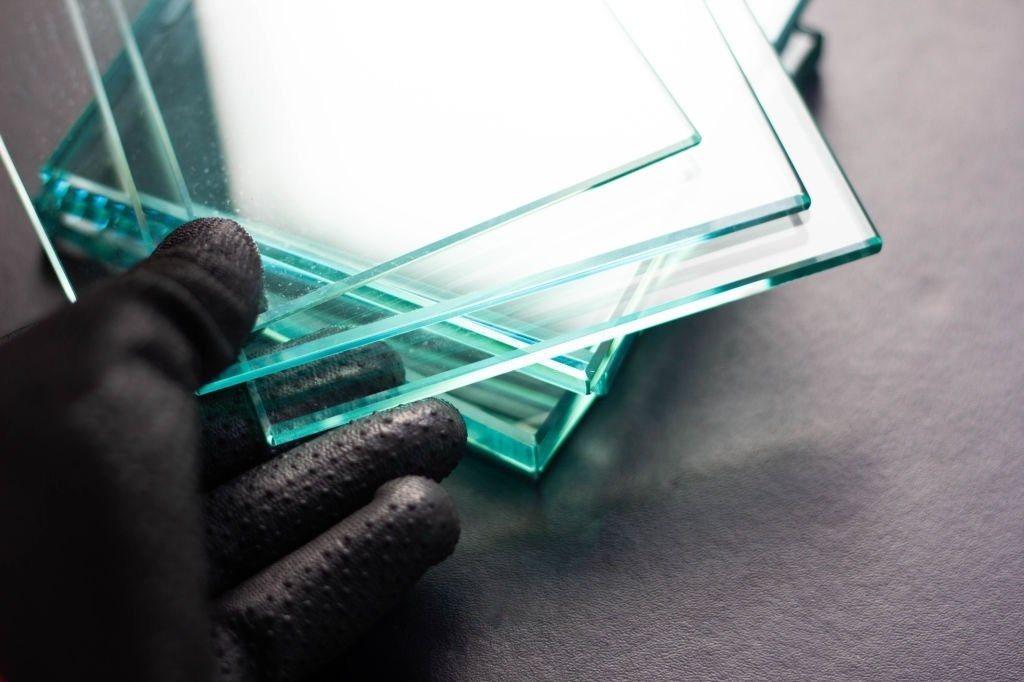

- Leather Gloves: While handling the glass pane, ensure your hands are well-protected by wearing sturdy leather gloves. These gloves will provide an adequate barrier between your skin and the newly annealed – and potentially sharp – glass pane.

- Understanding the Risks: It’s important to note that once tempered glass has undergone the annealing process, it loses its safety glass status. This means that if it breaks, it can create dangerous sharp edges rather than harmlessly crumbling into small, rounded pieces like regular safety glass.

Remember, these safety measures are not optional; they’re an essential part of the procedure when working with annealed tempered glass. Prioritizing your safety can help ensure a successful and accident-free project completion.

Interesting Fact: Tempered glass is approximately four times stronger than “ordinary,” or annealed, glass; and unlike annealed glass, which can shatter into jagged shards when broken, tempered glass fractures into small, harmless pieces. This is why it’s called “safety glass.

✔ Step#3: Making the Cut Line

In your process of working with glass, a critical step involves creating a precise cut line. This step serves as a guide for where you plan to cut. It is essential to ensure accuracy and prevent any unwanted deviations or curves in your final cut.

1. Identifying the Desired Cut Location

Your first task is to determine where on the glass pane you want to make your cut. This decision may depend on the final use of the glass piece, whether you’re fitting it into a window frame, creating a custom mirror, or crafting a distinctive decor piece. Measure the spot accurately using a measuring tape or ruler to ascertain the correct dimensions.

2. Using a Straight Edge

The next step involves leveraging a straight-edge tool. A metal ruler can be an excellent choice for this purpose due to its rigidness and durability. The straight edge will serve as your guide when marking the line on the glass surface.

3. Marking the Line

Now, place your chosen straight edge along with the measured spot on your glass pane. Hold it firmly to avoid any movement that could lead to inaccuracies in marking.

Using a permanent marker, draw a line along the edge of your straight tool. This line represents where you plan to cut and should be visible and precise.

This marked line not only provides a path for you to follow when cutting but also helps ensure that your cut is straight without any unintended curves or angles.

Pro Tip: For best results, consider marking both sides of the glass pane according to measurements. It provides better visibility and accuracy during cutting process.

Remember, precision during this stage greatly influences the success of your final glass-cutting project. Therefore, take your time and ensure everything is correctly measured and marked before proceeding with cutting.

✔ Step#4: Score the Glass Surface Using a Glass Cutter

Scoring the glass surface is a critical step in achieving a clean and precise cut. Here’s how:

- Position the Glass Cutter: Hold your glass cutter like a pencil, keeping the straight edge of the cutter aligned with your marked line. This alignment will serve as your guide when scoring the glass surface.

- Apply Controlled Pressure: Gently but firmly press your cutter into the glass. The pressure should be enough to make an impression on the glass, but not so much that it risks breaking it. Remember, exerting too much pressure can lead to cracks and chips, damaging your entire project.

- Run the Cutter Along Your Marked Line: Begin at one end of the marked line and run your cutter along its entire length, maintaining consistent pressure throughout. Try to ‘connect’ with the sound of scoring; it should produce a consistent, even sound if done correctly.

Note: Listen for a steady hissing sound when you’re scoring. This indicates that you’re applying just the right amount of pressure.

- Achieve It in One Go: Strive to score the entire line in one continuous motion without lifting your cutter off the glass surface. This avoids creating two separate lines which can lead to shattering or uneven edges.

Pro Tip: Try practicing on a scrap piece of glass first to get a feel for how much pressure to apply while scoring.

Remember, practice makes perfect! So don’t worry if you don’t get it right on your first try. With patience and repeated attempts, you’ll soon master this technique and achieve clean, precise cuts every time.

✔ Step#5: Placing the Wooden Dowel

The fifth step in the process requires you to place a wooden dowel under the freshly scored line on your piece of glass.

Choosing the Right Dowel

The dowel you choose for this step should measure approximately 1/4 inch or 0.64 cm in diameter. This size is appropriate for most projects as it provides an optimal balance between stability and precision when breaking the glass along the scored line.

Positioning the Dowel

The placement of the dowel is critical to achieving a clean, smooth cut. It should be positioned directly beneath the scored line. Accurate alignment prevents unwanted shattering or cracking of the glass when pressure is applied.

To ensure proper placement:

- Place the dowel on a stable surface

- Carefully lay your piece of glass on top, aligning the dowel with the scored line

Avoiding Common Mistakes

One common mistake to avoid when placing your dowel is using one that’s too long. A longer dowel can lead to an uneven break, resulting in an imperfect edge that may require additional sanding or pose a safety hazard.

Remember, precision is key in every step of cutting glass, from scoring to breaking, to achieve a sleek and clean final product.

Pro Tip: Always double-check your dowel placement before applying pressure to break the glass along your scored line. This extra moment of caution can save you from having to start over due to an imprecise break.

✔ Step#6: Apply Pressure

This stage is crucial in the glass-cutting process. In this step, you’ll have to exert substantial pressure on both sides of your strategically placed wooden dowel.

The application of pressure should be sudden and direct, without any pauses or hesitations. A pause during this step could lead to an imperfect cut, causing the glass to fracture along an unintended line. This single action determines whether your glass piece will break cleanly along the scored line or shatter unpredictably.

Here’s a breakdown of how you should proceed:

- Position Your Hands: Place your hands on either side of the dowel. Make sure they are in a comfortable position as you’ll need to apply force evenly.

- Apply Sudden Pressure: With your hands in position, apply a sharp and swift downward pressure. Remember, this action should be quick and straight, without any pause.

- Use Both Hands Equally: It’s important to use both hands to create equal pressure on both sides of the dowel. Uneven pressure could lead to an irregular break which may ruin the shape of your glass piece.

By following these steps correctly, you will successfully divide your piece of glass into two separate parts according to your measurement.

Note: The key to a successful break is the sudden yet controlled application of force. Too much hesitation or unevenness can lead to unfavorable results.

Ultimately, mastering this step will take practice and patience. Don’t be discouraged if you don’t get it right on the first try—every expert was once a beginner!

✔ Step#7: Sand the Edge

This is the final stage in the process of cutting a glass pane. Here, your task will be to sand down the freshly cut edges of the glass. This step is crucial for a couple of reasons:

- Safety: It decreases the risk of accidents that can happen due to sharp and uneven glass edges.

- Quality: It gives your glass piece a professional finish and smooth feel.

For this operation, consider using coarse 10-grit sandpaper, which is an excellent tool for smoothing out jagged edges on glass.

Here’s how you should proceed:

Materials Needed

- Coarse 10-grit sandpaper: This type of sandpaper is preferable due to its rough texture which is perfect for grinding down harsh edges.

- Safety equipment: Always maintain appropriate safety measures. Protective eyeglasses and hand gloves are essential during this step to shield you from potential injuries.

Procedure

- Position your sandpaper: Hold your sandpaper at a 45-degree angle to the glass edge.

- Begin Sanding: Apply gentle yet firm pressure as you move the sandpaper back and forth over the edge. Be sure to cover all areas uniformly.

- Check Smoothness: After a few strokes, pause to run your gloved hand along the edge to check if it’s smooth enough. If any rough spots persist, continue sanding until you achieve the desired smoothness.

Note: Always keep your safety gear on while checking the glass edge. Never use bare hands even if you think it’s adequately smoothed out.

By diligently following these steps, you’ll yield a well-finished piece of glass that’s safe to handle and pleasing to touch. Remember, practice makes perfect – don’t be discouraged if it takes a few attempts to get it just right!

Essential Advice and Safety Tips

The process of cutting glass might seem straightforward, but it requires precision and attention to detail. Even a small mistake can lead to an accident, potentially resulting in serious injury. Therefore, it’s vital to follow the procedure meticulously.

To ensure your safety and achieve the best possible results, here are some key points to remember:

- Initial Cleaning: Thoroughly cleaning the glass before you start is vital. This removes any dust or debris that could interfere with your cut, ensuring a smooth and accurate result.

- Safety First: Always prioritize your safety during the procedure. Wear protective eyewear and gloves from start to finish to protect yourself from potential injuries.

- Use Quality Tools: The marking ruler should be sturdy and straight for precise measurements. Similarly, opt for a permanent marker with deep color for visible lines on the glass.

- Single Stroke Cutting: It’s crucial not to run the glass cutter over the same line twice. This could cause irregularities in your cut and increase the risk of accidents.

- Apply Medium Pressure: When applying pressure on the glass with your cutter, aim for a medium level of force. Too much pressure may lead to scratches or cause the glass to break unexpectedly.

- Right-sized Dowel: The wooden dowel used should be neither too large nor too small – its size should be proportionate to your cut.

- Handle Dowels Safely: Never place your hands directly on top of the dowel – sharp pieces of glass can easily penetrate your palms if mishandled.

- Never Skip Sanding: Sanding is an indispensable step that ensures safety by smoothing out sharp edges. Do not skip this step under any circumstances.

By following these safety guidelines diligently, you’ll significantly reduce risks while ensuring a perfect cut every time.

As a final recommendation, if you’re looking to create custom-sized glass pieces, consider purchasing annealed glass. This type of glass is more straightforward to cut into various shapes compared to toughened glass. However, if you find a piece of tempered glass at home that needs to be repurposed, it can certainly be used with the right precautions and techniques.

FAQs(Frequently Asked Questions)

Tempered glass is a type of safety glass that is processed by controlled thermal or chemical treatments to increase its strength compared to normal glass.

The annealing process involves a carefully controlled heating and cooling of the glass to relieve internal stresses, making the glass more workable and less prone to shattering.

Professional assistance is recommended because the annealing process weakens the glass, making it more susceptible to shattering. Professionals have the expertise and tools to handle tempered glass safely.

The key steps include cleaning the surface, ensuring safety measures, marking the cut line, scoring the glass surface using a glass cutter, placing a wooden dowel, applying pressure, and sanding the edge.

Coarse 10-grit sandpaper is preferred for sanding the edge of tempered glass. It is essential for achieving a smooth and safe edge.

Positioning the sandpaper at a 45-degree angle helps to create a smooth and even edge on the tempered glass, reducing the risk of injury from sharp edges.