Table of Contents Show

Precision metal fabrication is a critical process in today’s manufacturing industry. It involves the shaping and forming of metal components to very precise tolerances. Here are some reasons why precision metal fabrication is so important:

It Helps to Create Products with A High Level of Accuracy and Quality

Precision metal fabrication plays an important role in ensuring that products are made with a high level of accuracy and quality. The process involves cutting, shaping, and joining metals to create the desired product.

Fabricators use a variety of tools and machines to perform these tasks, including CNC machines, lathes, and presses. The precision of these machines allows for the creation of products with tight tolerances and a high degree of accuracy.

Read Also:

It Can Be Used to Create Products with Very Intricate Design

Precision metal fabrication is a process that allows manufacturers to create products with very intricate designs. Using a variety of techniques, including stamping, casting, and machining, metal fabricators can create products with extremely precise dimensions.

This type of manufacturing is often used for products that require tight tolerances, such as medical devices and aerospace components. In addition, precision metal fabrication can be used to create products with complex shapes and detailed features.

As a result, this manufacturing process is an important tool for creating a wide range of products.

It Helps to Save Material Costs by Using Less Material Overall

When it comes to manufacturing metal products, there is a lot of room for error. Even a small mistake can result in wasted material, which can add up to big costs over time.

That’s where precision metal fabrication comes in. By using advanced technology and precise measurements, metal fabricators can create products that use less material overall.

This not only helps to save on material costs but also reduces the amount of waste that goes into landfills. In addition, precision metal fabrication can also help to improve the quality of the finished product.

By ensuring that all of the pieces fit together perfectly, manufacturers can avoid defects and ensure that their products meet the highest standards. As a result, precision metal fabrication is an essential part of any modern manufacturing process.

It Can Help to Improve the Strength and Durability of Products

Businesses that rely on metal products understand how important it is to have those products fabricated with precision. After all, even a small error can cause the finished product to be weaker and less durable. In some cases, it can even render the product unusable.

That’s why businesses that require metal products turn to companies that specialize in precision metal fabrication. By working with experts, businesses can ensure that their products are fabricated to the highest standards and will be able to withstand the rigors of everyday use.

It Helps to Improve the Aesthetics of Products

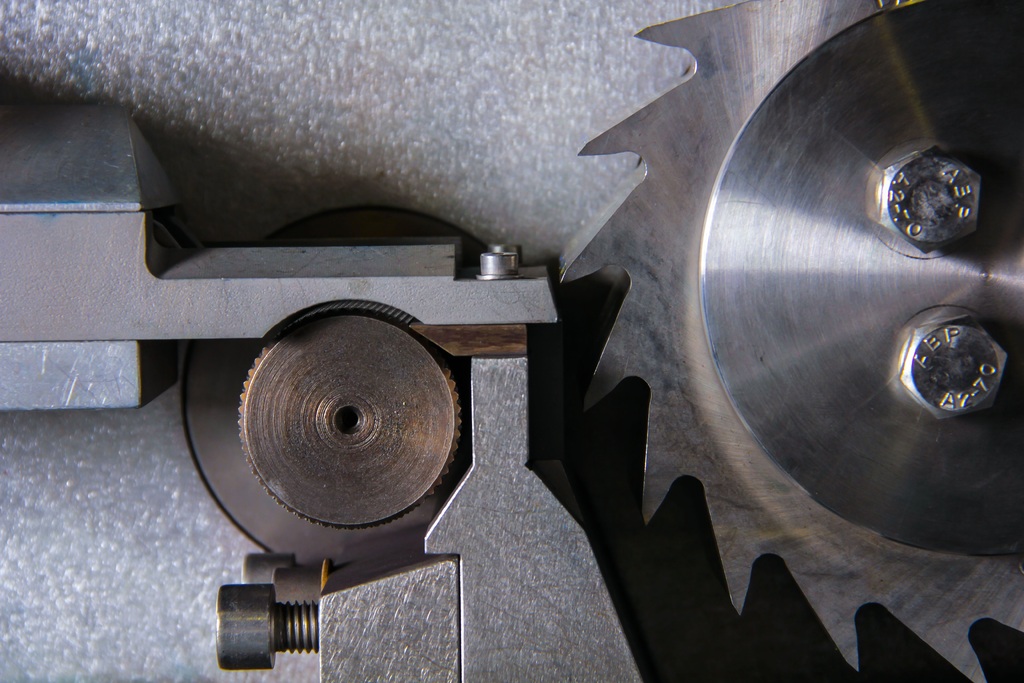

As anyone who has ever looked at a sheet of metal knows, the edges are often jagged and uneven. This can be especially true of thicker pieces of metal, which are often cut with power tools like saws and torches.

Precision metal fabrication helps to improve the aesthetics of products by creating clean, precise cuts that give the metal a smooth, finished edge.

As a result, products that undergo precision metal fabrication often have a more polished and professional look. In today’s competitive market, this can be the difference between a product that sells and one that doesn’t.

It Can Help to Reduce Production Time and Costs

As anyone in the manufacturing industry knows, time is money. The longer it takes to produce a product, the higher the production costs will be. That’s why precision metal fabrication can be so important. By using high-tech machines to create metal parts with extreme accuracy, production times can be drastically reduced.

In addition, because there is less waste material, costs are also reduced. As a result, precision metal fabrication can be a critical tool in the manufacturing process, helping to improve efficiency and reduce costs.

It Can Help to Create Products That Are More Sustainable and Environmentally Friendly

As the world becomes increasingly focused on sustainability, many manufacturers are looking for ways to create products that are more environmentally friendly. One way to do this is through precision metal fabrication. By using advanced manufacturing techniques, it is possible to create metal products with very tight tolerances.

This can result in a reduction in the amount of raw material waste, as well as lower energy consumption during the manufacturing process.

In addition, precision metal fabrication can also help to create products that are long-lasting and require less maintenance. As a result, precision metal fabrication is an important tool in the quest to create more sustainable and environmentally friendly products.